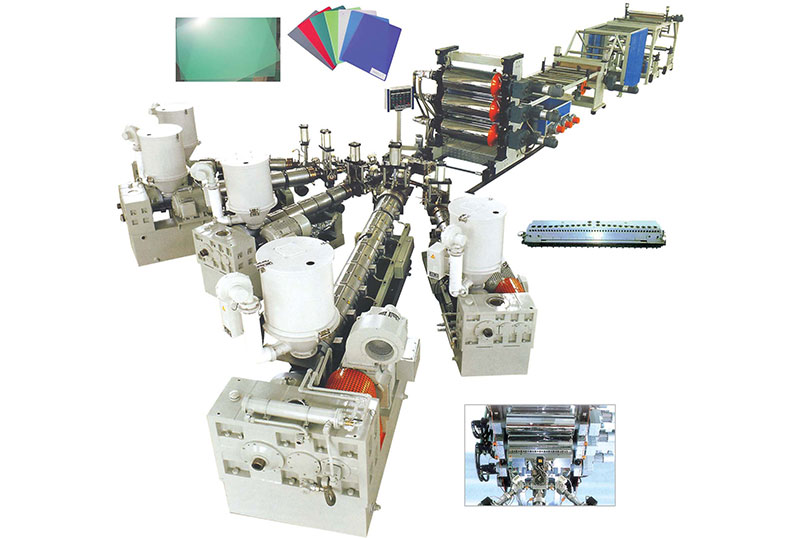

I-WPC PVC Crust Foam Board Extrusion Line

Imininingwane Imingcele Yezobuchwepheshe

(Isithombekuphela ngereferensi)

Incazelo evamile

1, Usayizi womkhiqizo: ububanzi 1250mm/ubukhulu:2-30mm (Ngokusekelwe kwimfuneko yekhasimende)

2, Izinto Eziyinhloko: I-WPC Compounding, ukucubungula izithasiselo kanye ne-ejenti yokugcwalisa

3, I-Extruder: SJSZ80/156 i-conical double screw extruder

4, Okukhiphayo: cishe ku-7ton / ngosuku

5, Ukushisa kwamanzi okupholisa: <15℃ Ukucindezela komoya: > 0.6Mpa

6, Power supply: 3Phase / 380V/50HZ (Ngokusekelwe imfuneko yekhasimende)

B.Imininingwane Amapharamitha Omsebenzi wengxenye ngayinye

1. Isikulufa Isilayishi esizenzakalelayo

2. SJSZ80/156 I-Conical Double Screw Extruder

| ﹡Isikulufu, ukwakhiwa kwemigqomo nokukhiqiza kudonsa ubuchwepheshe obuphambili baseYurophu ﹡Isikulufu kanye nempahla yomphongolo:38CrMoAlA, i-Nitriding iphathwa ﹡thatha izingxenye zikagesi ezidumile ezinekhwalithi ephezulu yokusebenza engaguquki.Isb: I-RKC noma isilawuli sezinga lokushisa i-Omron, isilawuli sesivinini se-ABB, i-low-voltage breaker isebenzisa i-Schneider noma i-Siemens ﹡I-gearbox isebenzisa i-torque ephezulu, umsindo ophansi, ibhokisi legiya legiya eliqinile ﹡Isistimu yokuzivikela: isivikelo sokumisa esizenzakalelayo sokulayisha ngokweqile kwemoto isikulufu displacement isivikelo sokumisa okuzenzakalelayo Idivayisi ye-alamu yokugcoba uwoyela wokuthambisa | |||

| 1 | Isikulufa Ububanzi | mm | ¢80/156 |

| 2 | Ubude besikulufa | mm | 1800 |

| 3 | Isivinini sokuzungezisa isikulufu | r/min | 0-37 |

| 4 | Impahla ye-Screw kanye ne-Barrel | / | 38CrMoAlA Ukwelashwa KweNitrojeni |

| 5 | Ukujula kwecala le-nitrate | mm | 0.4-0.7mm |

| 6 | Ubunzima be-nitrate | HV | 》950 |

| 7 | Ukuqina kwendawo | Ra | 0.4un |

| 8 | Ukuqina kwama-alloys aphindwe kabili | HRC | 55-62 |

| 9 | Ukujula kwama-alloys aphindwe kabili | mm | 》2 |

| 10 | Amandla Okushisa | KW | 36 |

| 11 | Ukushisa Kwemigqomo | / | I-Aluminium Heater yokusakaza |

| 12 | Isikulufa sokulawula izinga lokushisa | / | Ukulawula ukushisa komjikelezo okuzenzakalelayo |

| 13 | Izindawo zokushisisa | / | 4 |

| 14 | Ukupholisa | / | ukupholisa i-blower |

| 15 | Ukulungiswa kwezinga lokushisa kwe-screw core | / | Ngamafutha okuqhuba umbuthano |

| 16 | Ubuningi besikulufa | 2 ama-pcs | |

| Uhlaka lomshini | Welding of steel pipe kanye iron plate | ||

| Ibhokisi legiya | |||

| 1 | Izinga elisebenzayo | / | JB/T9050.1-1999 |

| 2 | Impahla yegiya neshaft | / | Adopt high power alloy, carburizing kanye nokucisha, ukugaya |

| 3 | Ukunemba kwegiya nobulukhuni | / | 6grade, HRC 54-62 |

| 4 | Ukuvalwa kwamafutha | Konke ukufakwa uphawu kusebenzisa imikhiqizo emihle | |

| 5 | I-Screw Safeguard | / | I-alamu ezenzakalelayo yokususwa kwesikulufa |

| 6 | Ibhrendi | I-DUOLING (JIANGYIN) | |

| 7 | igiya elithwalayo | I-NSK | |

| 8 | igiya elithwala IZINTO | 20CrMnTi Nitriding izinyo eliqinile | |

| Idivayisi yokuphakela umthamo | |||

| 1 | Ukulawula isivinini sokudla | / | Ukuguqulwa kwemvamisa ye-ABB |

| 2 | Ingalungiswa ngokwehlukana noma ivumelaniswe ukulungisa nge-extrusion. | ||

| 3 | Ukondla injini 1.5kwMaterial insimbi engagqwali | ||

| Motor kanye nesistimu kagesi | |||

| 1 | Amandla Ezimoto | KW | 75(AC motor) |

| 2 | Imodi yokulungisa isivinini | / | Ukuguqulwa kwemvamisa eguquguqukayo |

| 3 | Umthamo Wokukhiphayo | Kg/h | 400 |

| 4 | Isilawuli Sezinga lokushisa | / | I-RKC, Japan |

| 5 | I-inverter yemvamisa | / | I-ABB |

| 6 | Isixhumi se-AC | / | Siemens |

| 7 | Amandla kagesi | / | Ngokwemfuneko |

| 8 | Motor brand | Siemens | |

| 9 | Ukuphakama kwe-eksisi ye-Extruder | mm | 1000 |

| 10 | |||

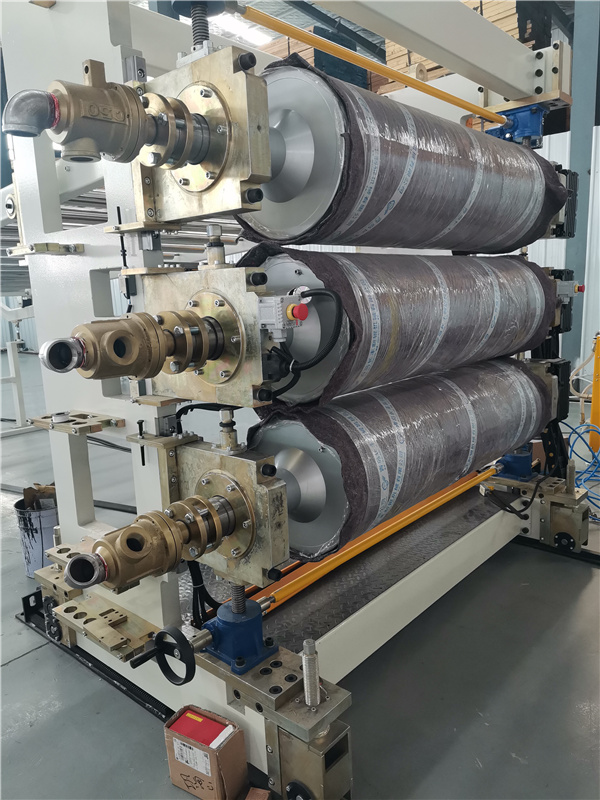

3. I-Die head kanye nokulinganisa Izibungu (kuhlanganise nesilawuli sezinga lokushisa lesikhunta)

| Into | Incazelo | |

| Idivayisi elawulayo enepulaki yokuklinywa: Isethi engu-1 yodebe olufayo.Udebe olungaphezulu lwe-die lungalungiswa futhi udebe olungezansi lungashintshwa.Ifakwe isibambi sokufa nge-adjustable die lifting.I-mold lip ifakwe idivayisi yamafutha okudlulisa ukushisa okujikelezayo, ifakwe umshini wokushisa wesikhunta. Ububanzi obusebenzayo bekhanda lokufa: 1350mm Imodi yesiteshi: ishaneli yokuphanyeka kwezingubo yamukelwa Ububanzi bomkhiqizo: 1220mm Ubukhulu bemikhiqizo yebhodi legwebu: 3-25mm Isigaba sokushisisa: Zone 7 Idiyidi yenziwe ngensimbi ye-alloy yekhwalithi ephezulu kanye ne-die steel forgings, futhi ingaphezulu lomgijimi ongaphakathi lifakwe i-chrome plated futhi lipholishwe. Isakhiwo sesikhunta: isakhiwo sesikhunta sithatha ubuchwepheshe obungenisiwe, futhi ingaphakathi le-mold cavity lihlanganiswe ne-chromium eqinile futhi lipholishelwe esibukweni esikhanyayo. Ukulungiswa kokuqina: amabhawodi aguquguqukayo abekwe ku-die lip, angalungiswa lapho kukhiqizwa amapuleti anobukhulu obuhlukile. Ifomu lokushisa: insimbi engenasici yokushisa kagesi isetshenziselwa ukufudumeza, ngokukhishwa okufanayo kanye nokuzinza okuhle. I-Mold trolley, uhlobo lwebakaki, nesondo lokuhamba. Material: isikwele tube steel plate welding isakhiwo kwaqiniswa Indlela yokulungisa: ukulungisa isikulufu Ubude bokulungisa: 100mm | ||

Umshini webhodi legwebu le-PVC Izingxenye ezisele :Uhlu lwezesekeli:

| NO | Igama lezingxenye ezisele | Ubuningi |

| 1 | Sakaza iheater ye-aluminium yendawo engu-1 | 1 ama-pcs |

| 2 | Ifeni yomoya epholisa umgqomo | 1 ama-pcs |

| 3 | I-Spanner yesikhunta | 1 ama-pcs |

| 4 | abathintwayo | 2 ama-pcs |

| 5 | Ama-thermocouples | 5 ama-pcs |

| 6 | Ukushisa izinti zama-abrasives | 5 ama-pcs |

| 7 | i-copper feeler gauge | 1 ama-pcs |

| 8 | amabhawodi okulungisa afe | 5 ama-pcs |

| 9 | Imithombo yokudla yomshini wokudla | 2 ama-pcs |

| 10 | Ipayipi le-pe lomshini wokudla | 2 ama-pcs |

| 11 | izixhumi zepayipi lomoya | 5 ama-pcs |